Waterproofing membranes are crucial elements in construction projects, used to ensure the buildings, roofs, and other structures are protected from water damage whilst preventing dangerous conditions such as mould, mildew, corrosion, or rot. The type of membrane that you should use depends on the type of structure and the area of application, whether it be internal or external.

Below we have listed 3 key things for you to consider when considering a membrane for your project.

1. Regulatory Compliance Testing

Ensuring that the membrane that you are using complies with the regulatory requirements as outlined within the NCC (National Construction Code) is critically important.

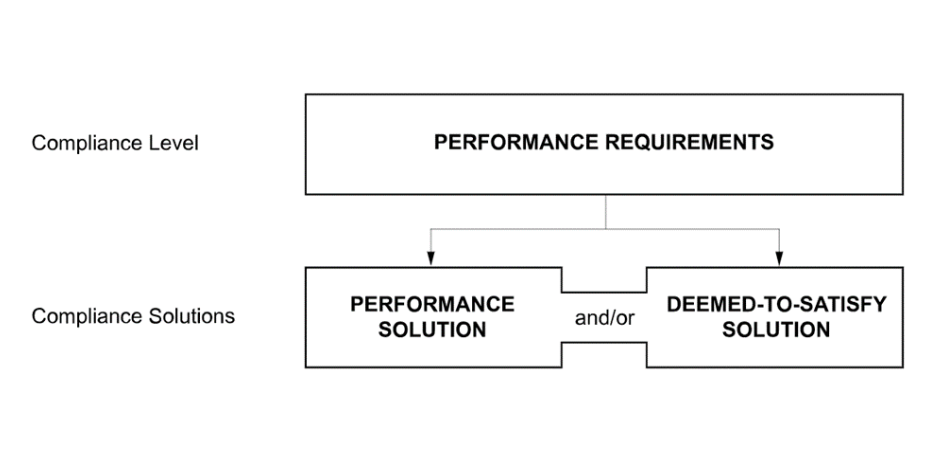

Figure A2G1 from the 2022 NCC (shown below) demonstrates that Performance Requirements may be satisfied by either a Performance Solution and/or a Deemed-To-Satisfy Solution.

[Figure A2G1 from the 2022 NCC]

Internal Wet Areas

In order to maintain healthy living conditions and to preserve the integrity of a building and its property, it is crucial to avoid the accumulation of water in internal wet areas. This not only prevents potential damage to the building, but also ensures the safety and well-being of its occupants. Equally important is the prevention of water damage to the internal components of the building, which can result in costly repairs and disruptions.

To comply with the Deemed-To-Satisfy Solution for Internal Wet Areas, as per Clause F2D2 of the 2022 NCC, waterproofing membrane for internal wet areas must be designed and installed in accordance with AS 3740, and the waterproofing membrane be compliant to AS 4858.

External Above-Ground Areas

Preventing water from entering and accumulating within a building is crucial to avoid creating unhealthy conditions and damaging building elements. This involves careful design to minimise the risk of water ingress and redirecting it away from the building to prevent damage to nearby properties. It is important to take proactive measures to ensure that your building remains in good condition and to prevent any water-related damage from occurring. By ensuring that your building has adequate waterproofing, you can help to protect your property and ensure that it remains safe and healthy for all occupants.

To comply with the Deemed-To-Satisfy Solution for External, Above Grade Areas, as per Clause F1D5 of the 2022 NCC, waterproofing membranes for external, above-ground areas must be designed and installed in accordance with AS 4654.2, and the waterproofing membrane be compliant to AS 4654.1.

It is important to appreciate that there are inherent differences between AS 4858 and AS 4654.1, and as such these standards cannot and should not be used interchangeably.

2. Suitability for Use

The inherent properties of a membrane play a crucial role in determining its overall effectiveness and suitability for use for the proposed application. It is essential to carefully consider each area of a building’s integral requirements when selecting a high-quality waterproofing membrane to ensure long-lasting protection against water ingress. For example, a membrane designed for under-tile use, is not likely to be appropriate for usage in a planter box, and a membrane designed for use in a planter box, is not likely to be appropriate for usage on an exposed rooftop.

It is important that the correct membrane is selected for each application, a one size fits all approach is never appropriate when it comes to the selection and specification of waterproofing membranes. Consult our Specification Team for any project-specific advice that you require.

It is always advised to refer to the product technical data sheet.

[example of product technical data sheet]

3. Curing

To ensure the long-term performance of any membrane system, it is critical that it is allowed to properly cure before the installation of any overburden finishes or being placed into service. The time needed for a membrane system to properly cure may vary depending on the type of product used and the ambient conditions.

Inherently the ambient conditions for internal areas and external areas are likely to differ, and this is likely to have a significant impact on the curing of a membrane system. The same membrane installed to both internal and external areas, may have a vastly different curing time in each area, depending on variables such as temperature, relative humidity, and airflow. As such, specific consideration should be given to the curing of a membrane, in relation to both the product type as well as the area of application. For specific information, contact one of our experienced Technical Representatives.

Selecting the right waterproofing membrane is crucial for protecting your building against water damage and ensuring the safety and well-being of its occupants. Compliance with regulatory requirements, suitability for use, and proper curing are all essential factors to consider when selecting and installing a waterproofing membrane. If you have any questions or need project-specific advice, our Specification Team and Technical Representatives are always available to assist you.

© 2025 Tremco Incorporated