Therefore, it is important to properly select and apply the right waterproofing membrane to ensure the longevity of any construction project.

PVC waterproofing membranes are made from polyvinyl chloride (PVC). This synthetic material is used to create a watertight barrier in various applications and is known for its durability, flexibility, and resistance to water and chemicals.

PVC waterproofing membranes have gained significant popularity in the construction industry due to their numerous benefits. In roofing, PVC is combined with a plasticizer to form a flexible, single-ply membrane that can last for decades without losing its reliability and positive characteristics.

PVC single-ply membranes were first installed in Europe in the 1960s and the United States in the 1970s. PVC membranes can be ballasted, mechanically attached, or fully adhered for installation — further adding to their versatility.

Superior Waterproofing Properties:

PVC waterproofing membranes are known for their exceptional ability to prevent water infiltration. These membranes are designed to create a watertight barrier, ensuring that no moisture can penetrate the structure. This feature is particularly important in areas prone to heavy rainfall or high levels of humidity. By effectively preventing water penetration, PVC membranes help protect the building from potential water damage, such as leaks, mould, and deterioration.

Due to its water vapour transmission properties, these membranes can be installed over damp substrates and can easily handle ponding or excessive accumulation of water. In addition, PVC membranes don't require curing time to become waterproof, and their thickness will remain constant throughout the entire project. Structures are protected immediately by PVC sheet membranes, and finishes can be applied over them immediately.

Flexibility and Durability:

One of the key advantages of PVC waterproofing membranes is their flexibility. These membranes can easily adapt to various surfaces and shapes, making them suitable for both flat and curved structures. Whether it is a roof, basement, or foundation, PVC membranes can be seamlessly installed to provide comprehensive waterproofing protection. Their robustness ensures that the waterproofing system remains intact for an extended period, minimizing the need for frequent repairs or replacements.

Energy Efficient and Low Maintenance:

PVC waterproofing membranes offer excellent insulation properties, contributing to energy efficiency in buildings. By preventing water infiltration, these membranes help maintain a stable indoor temperature, reducing the need for excessive heating or cooling.

PVC single ply membranes have a high reflectivity index, meaning they reflect the sun’s heat and UV radiation, keeping your building cooler in the summer, and requiring very little maintenance. This, in turn, leads to lower energy consumption and cost savings in the long run, whilst being attractive as a low-maintenance option.

Extremely Weather Resistant:

PVC membranes are highly durable and resistant to UV radiation and can withstand extreme weather conditions, including high winds and hail, without leaking or sustaining damage that could be caused in a storm. One of the main benefits of a PVC membrane is that it is resistant to lightning strikes and fire hazards by withstanding high heat and flames without burning, making it an ideal choice for commercial applications. Their flame-retardant properties can help to keep your building safe in the event of fire.

Environmentally Friendly:

PVC waterproofing membranes are environmentally friendly compared to other traditional waterproofing methods. They are free from harmful substances like lead and mercury, making them safe for both human health and the environment. They are recyclable and can be repurposed into new PVC products, reducing waste that goes into landfill and promoting sustainability. Additionally, the long lifespan of PVC membranes minimizes the need for replacements, further reducing the environmental impact.

Easy Installation and Lower Costs:

PVC waterproofing membranes are relatively simple to install, making them a cost-effective solution for waterproofing projects. These membranes are available in rolls, easily unrolled, and laid on the desired surface. Being a lightweight plasticized material, it is easy for a contractor to install and does not require any additional structural support, making it ideal for buildings with low-slope roofs or flat roofs.

The installation process is straightforward and requires minimal time and effort. This ease of installation not only saves labour costs but also reduces the overall construction timeline.

Selecting the correct type of waterproofing membrane for your building or structure is essential and the quality of the material is a key factor. PVC waterproofing membranes have become increasingly popular in the construction industry due to their superior waterproofing properties, flexibility, durability, ease of installation, energy efficiency, and environmental friendliness.

By opting for PVC membranes, contractors and building owners can ensure long-lasting protection against water damage, ultimately enhancing the lifespan and durability of their structures. Incorporating PVC waterproofing membranes into construction projects is a wise investment that offers both functional and sustainable benefits.

Waterproofing

Internal vs External Waterproofing Membranes - What are 3 Key Considerations?

Waterproofing

Internal vs External Waterproofing Membranes - What are 3 Key Considerations?

Waterproofing membranes are crucial elements in construction projects. Discover 3 key considerations when choosing a membrane.

Flooring, Waterproofing

Navigating the Depths: Challenges in Waterproofing and Coating Basement Car Park Decks

Flooring, Waterproofing

Navigating the Depths: Challenges in Waterproofing and Coating Basement Car Park Decks

In this blog post, we will delve into the intricacies of waterproofing and coating basement car park decks...

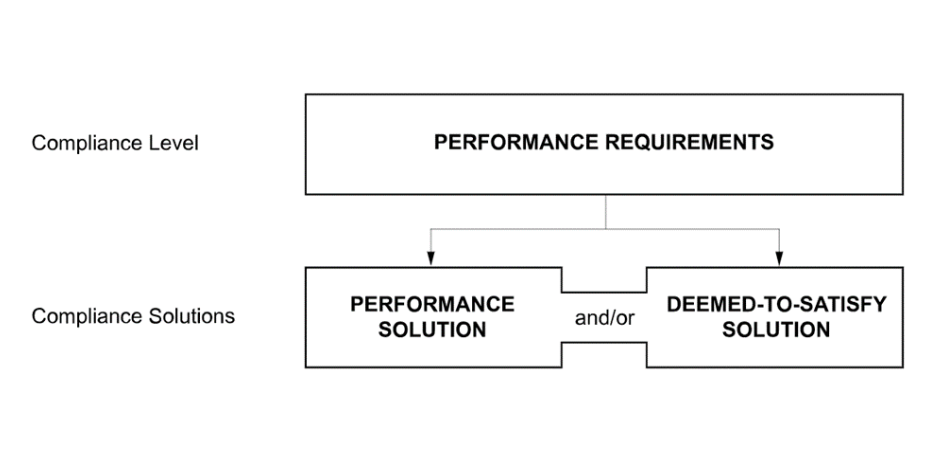

1. Regulatory Compliance Testing

Ensuring that the membrane that you are using complies with the regulatory requirements as outlined within the NCC (National Construction Code) is critically important.

Figure A2G1 from the 2022 NCC (shown below) demonstrates that Performance Requirements may be satisfied by either a Performance Solution and/or a Deemed-To-Satisfy Solution.

[Figure A2G1 from the 2022 NCC]

Internal Wet Areas

In order to maintain healthy living conditions and to preserve the integrity of a building and its property, it is crucial to avoid the accumulation of water in internal wet areas. This not only prevents potential damage to the building, but also ensures the safety and well-being of its occupants. Equally important is the prevention of water damage to the internal components of the building, which can result in costly repairs and disruptions.

To comply with the Deemed-To-Satisfy Solution for Internal Wet Areas, as per Clause F2D2 of the 2022 NCC, waterproofing membrane for internal wet areas must be designed and installed in accordance with AS 3740, and the waterproofing membrane be compliant to AS 4858.

External Above-Ground Areas

Preventing water from entering and accumulating within a building is crucial to avoid creating unhealthy conditions and damaging building elements. This involves careful design to minimise the risk of water ingress and redirecting it away from the building to prevent damage to nearby properties. It is important to take proactive measures to ensure that your building remains in good condition and to prevent any water-related damage from occurring. By ensuring that your building has adequate waterproofing, you can help to protect your property and ensure that it remains safe and healthy for all occupants.

To comply with the Deemed-To-Satisfy Solution for External, Above Grade Areas, as per Clause F1D5 of the 2022 NCC, waterproofing membranes for external, above-ground areas must be designed and installed in accordance with AS 4654.2, and the waterproofing membrane be compliant to AS 4654.1.

It is important to appreciate that there are inherent differences between AS 4858 and AS 4654.1, and as such these standards cannot and should not be used interchangeably.

2. Suitability for Use

The inherent properties of a membrane play a crucial role in determining its overall effectiveness and suitability for use for the proposed application. It is essential to carefully consider each area of a building’s integral requirements when selecting a high-quality waterproofing membrane to ensure long-lasting protection against water ingress. For example, a membrane designed for under-tile use, is not likely to be appropriate for usage in a planter box, and a membrane designed for use in a planter box, is not likely to be appropriate for usage on an exposed rooftop.

It is important that the correct membrane is selected for each application, a one size fits all approach is never appropriate when it comes to the selection and specification of waterproofing membranes. Consult our Specification Team for any project-specific advice that you require.

It is always advised to refer to the product technical data sheet.

[example of product technical data sheet]

3. Curing

To ensure the long-term performance of any membrane system, it is critical that it is allowed to properly cure before the installation of any overburden finishes or being placed into service. The time needed for a membrane system to properly cure may vary depending on the type of product used and the ambient conditions.

Inherently the ambient conditions for internal areas and external areas are likely to differ, and this is likely to have a significant impact on the curing of a membrane system. The same membrane installed to both internal and external areas, may have a vastly different curing time in each area, depending on variables such as temperature, relative humidity, and airflow. As such, specific consideration should be given to the curing of a membrane, in relation to both the product type as well as the area of application. For specific information, contact one of our experienced Technical Representatives.

Selecting the right waterproofing membrane is crucial for protecting your building against water damage and ensuring the safety and well-being of its occupants. Compliance with regulatory requirements, suitability for use, and proper curing are all essential factors to consider when selecting and installing a waterproofing membrane. If you have any questions or need project-specific advice, our Specification Team and Technical Representatives are always available to assist you.

© 2025 Tremco Incorporated